Mobile homes are becoming a great addition to modern architecture and home ownership as they have made life easier for many. One of the great features of mobile homes is that they are portable. However, moving such a heavy load will of course require the right amount of strength, which means you need to think carefully about mobile home axles to avoid any costly and unnecessary headaches

It is easy to forget about this part of your mobile home when it is in good shape and serving you properly, but it is possible you wake up one day and everything just won’t move. To avoid this proper maintenance is crucial and must be adhered to at all times because these moving parts are only useful when they move.

What to look for during maintenance

Debris

It is inevitable to find grease and gunk on any mechanical item with moving parts. Dirt can easily stick to grease, and if left unhandled, it causes a lot of difficulty moving. Cleaning this out regularly makes for better transport when the need arises.

Wear and tear

With every moving part comes the risk of wear. This is especially true for parts that don’t receive regular lubrication. Lack of lubrication leaves parts prone to roughly rubbing against each other. This may cause them to erode and that doesn’t look good or help with movement. Minimal lubrication also opens a door for rust and it happens faster where the axle is exposed to water.

Carrying out actual maintenance

Cleaning

Since dirt, dust and all kinds of debris are available throughout the year, hosing down your axles once a month or every two months reduces the likelihood of any of it collecting in any crevice, such as between brake pads.

Lubrication

The axle needs regular lubrication. You will notice a difference when you use it afterwards since it will probably be less creaky or less difficult to operate. Proper lubrication also provides increased life for metallic moving parts. Unchecked lubrication can leave parts under-lubricated and this leves room for friction and overheating.

Before you know it, the overheating causes the hub to seize. For some reason this tends to happen on the day you choose to take a long trip! The axle is therefore definitely better off lubricated and will save your pocket a good amount in replacement and/or repairs.

For those with oil bath hubs, you will know you need to put in new oil when the oil turns cloudy. Oil that is in good working condition should be golden. Cloudy oil is an indication that the oil has some water in it and this isn’t good for metallic moving parts.

Easier ways to get it done

Lubrication is simple work but may require a little patience. Open the oil cap, spin it around to get them to face down and then let the oil flow out. You want to be sure it all drains so leave it there a whole day or night and come back to it.

That seems like a long time, right? Well, make it go a little faster by pointing a hair dryer on ‘high’ setting at the hub. You could also point a heat gun but a hair dryer could be more easily accessible.

The hole the oil goes into is small and putting in the oil may take a while. You can make it easier by using a thumb pump. Plugs can come loose and leave you leaking oil but you can fix this by using a high temperature gasket sealant on the threads. They won’t come loose or leak and you get to enjoy better service from your trailer. Make sure you use the recommended oil.

Another odd but effective way to speed things up is to warm the oil in a microwave for a few seconds. Place the oil container in the microwave for a short time. Be careful not to overdo it. Look at the nozzle of the oil container. If it is tapered you can just cut a small part of the tip to leave you with a small hole, instead of looking for a thumb pump.

Try as much as possible to replace oil in warm weather. It is recommended that you check and change the oil at least twice a year or as the need arises.

Be sure to follow the instructions on what amount of oil to put in. Some say full while others say half. Filling it up too much risks popping out the back seals and that isn’t a pretty picture. The hubs may pop out if they overheat but that rarely happens. It shouldn’t happen regularly and if it does, you need to get it to a mechanic to have it checked.

Repacking bearings

The frequency of this particular maintenance aspect will depend on how often you move your home. Once a year is good, but you can do it once every two years if it isn’t used much. It involves taking out the wheels to reveal the wheel hub. That is where the bearings sit.

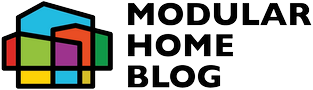

Start by removing the nuts so you can easily slide off the wheel. It would be easier if you used a wrench to remove the nuts. Go for the dust cap using a flathead screwdriver or a pair of channel locks, whichever one you find easier.

Look closely and you should see a cotter pin running through the spindle. Straighten out the cotter pin and carefully pull it out using needle nose pliers. Take out the castle nut there and the spindle.

Now you see the contents of the hub. Give it a slight wiggle as you aim to get the outside bearing loose. If done properly, you should be able to remove it by hand. Remember to put these items inside a clean container as you remove them. If you find a washer at this point, remove it too, although whether you find one or not will depend on your assembly.

Now go for the inner bearing and grease seal. You can use a flathead screwdriver to lift the grease seal which will then allow you to easily access the inner bearing with your hand. Get rid of the grease seal because you should replace it every time you have to repack the bearings.

You can easily get a replacement from a trailer parts store or online. Getting a replacement will require that you take note of the numbers inside the seal for reference. The other option is to physically measure the inner and outer diameters to find the size.

Easy does it

Carefully remove the bearings, wipe them down and check them for any kind of damage. This includes discoloring, scratches, pitting or excess wear. Any nicks may require that you get replacement bearings.

If they are still good, soak them in a solvent like acetone so as to properly loosen the remaining dirt and grime. Clean the inner bearing as well as the wheel bearing thoroughly and let them drain until they dry.

Take a look at the races, wipe out excess grease and carefully look at both the inner and outer races for damage. No damage means no replacement is required unless the bearings are damaged. Take note that replacing bearings automatically calls for replacing the races too.

Once the bearings dry up, grease them gently using high-temperature grease, making sure to remove any excess grease. Scoop up the grease using the bearing’s wide end. Imagine scooping up a tasty dip using chips and you’ll get it right!

The grease should go through the bottom all the way to the rollers. Grease them generously until done. Flip them over if need be so you can get every part properly greased.

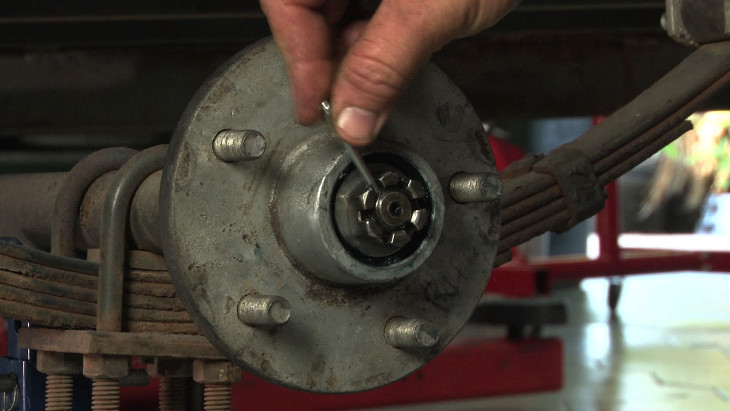

Clean the hub, removing any buildup. Place some grease inside the race and replace the inner bearing back into the hub. Clean the spindle and check for any excessive wear. Put the grease seal back. You may need to lightly tap it to help it sit right.

Carefully slide the hub onto the spindle, then the outer bearing and a washer if you have one. Put back the castle nut and tighten it. You might want to give the hub a little shake just to be certain it is sitting properly. Put the wheel back on and tighten the lug nuts.

Long term tightness isn’t healthy

You want to loosen the castle nut just a little, about a quarter turn, once everything is in place. This is because the bearings mustn’t be too tight or they will stop working before their time. Nobody wants premature failure, especially on something as useful as this.

It will also make it difficult for the wheel to rotate, which defeats the whole purpose of having bearings in the first place. Rocking the wheel at this point shouldn’t give you the sound of a moving hub. You should barely hear or feel it move if it is tight enough. Put the cotter pin back, bend it like it was and replace the dust cap. Repeat this same process for the other wheel as well.

This whole process could take about two to three hours depending on your speed and how careful you are when handling the parts. It may seem tedious at first, but you will definitely be glad you learnt how to do it when it has to be done while you are far away from home and your mechanic. You can ask your mechanic to have a look at it before you use it just in case you aren’t confident about your skills yet or you simply prefer to have them do it.

Regular maintenance goes a long way in preserving a mobile home axle, but it will get to that “point of no return” at some point. A time will come when you will have to let it go and that can be a difficult decision to make. It may be a long way off taking into account it may even last more than six years but it will come. How then, do you know it’s time to get a replacement?

When to replace an axle

A casual external look at this contraption may give you a picture of its health, but that isn’t always the case. There may indeed be signs like a little rust but you need to be sure that it has gotten to dangerous levels.

- Rust may be the first thing you notice. It could either be surface deep or could have gotten to extreme levels where it is already eating into the thickness of the axle. Take a hammer or heavy object and hit the axle. From the sound you will find out whether it is still thick enough or worn out to extreme levels. It could also break if it’s gone too far, so be prepared for that possibility. If it is only on the surface and it bothers you, you can paint over it to keep it from rusting further.

- A rattling or wobbly feeling is not good. This could be a sign that the axle is getting dangerously close to falling off. Take a look at the bottom because you may see very minimal damage at the top and assume that the situation is the same all the way through. It is possible for the axle to rust through until a wheel breaks off! Do you really want to be caught in such a situation?

- If the wheels look more deflected normal or the deflection isn’t equal on each side, there is a problem. The wheels normally have a slight deflection so that when the weight of the load is applied on the wheels everything aligns itself and the deflection draws closer to a zero valve. If this distance is a little further out it could be an indication of a weakened axle.

- Excessive wearing on the tires is obvious. Tires will wear out, but when this happens at an irregular rate, it shows an underlying problem. Where the spindle is bent, the whole contraption bends towards one side and the inside of the wheel on the affected side wears out considerably faster than the other.

Why you should replace your axle

The biggest reason for a replacement is safety. Axles are built to carry heavy loads, but imagine this piece of equipment falling apart when ferrying something heavy and costly. It can cause injury and irreversible damage to property and even human beings that could be in the way.

Damage to items may be costly and injuries to people may require a hospital visit, which costs money too. It is definitely safer and cheaper to replace it.

Using it when it is faulty causes a lot of instability. Negotiating simple corners can cause further damage to the axle and possibly the load as well.

Alternative remedies to replacement

If the only problem identified is rust and there isn’t evidence to show that the rust has eaten deep into the axle, a good option would be to paint over the rust. It may have already started flaking and this looks horrible and makes you look bad in the process, so it definitely needs fixing.

Take out the wheels and undo the U bolts. If the bolts are too rusted, you can simply cut them off using an angle grinder b. You’ll need to replace them, but they aren’t expensive so that shouldn’t worry you. Take the axle out, grind it back using the angle grinder again but with a suitable brush or disc.

Prime it and then paint. Finish off with a spray of tectyl. This will give it another 10 years or so and tectyl keeps rust away even longer.

When replacing the bolts, go for galvanized ones instead of zinc and spray them with tectyl too. You should replace hubs and bearings too if they are overly rusted so as to keep the machinery operating smoothly for several more years.

Things to Check As You Use Your Mobile Home to Ensure Safety

You’ve conducted all your maintenance and everything is looking good for the next year or so unless you move it often. An opportunity to use it may come your way and the excitement to bring out the contraption will definitely be something to look forward to, especially after diligently fixing it. You will literally be enjoying the work of your hands.

Before you dive in, it is important that you conduct a few checks. Just like you would check your car for tire pressure, oil level, fuel level, proper positioning of the mirror and any other thing you deem important, a mobile home requires the same due diligence before use. Here are a few of the important ones.

Check the mechanics

You know where to find the bearings now so you can use that knowledge to check whether they are loose. Check the axle bearings for any damage and re-grease them if need be. Remember, re-greasing and repacking the bearings means that you must get a new grease seal. Check the lug nuts before you leave and every 300 miles once you set off.

Brakes

Look for cracks, dirt and any items that shouldn’t be there. Remove any unwanted items and replace brakes if need be. You need them in top shape. Apart from safety, faulty brakes can cause axle damage and bearing issues in the long run.

Tires

Pressure and excessive wear are the most common things to look at with wheels. The tire pressure should be at the recommended level to avoid accidents and maintain a comfortable ride. Overly worn out tires definitely need to go. You also need to recall the age of your tires.

A tire’s lifespan is six years. After this, they just need to be replaced, whether you’ve been using them or not. It really is a huge risk using old tires for any kind of work.

Speed

Everything is in good shape and you are good to go. The road is clear and beautiful and you couldn’t be enjoying it more. Be careful not to drive too fast, though, because this can cause a little sway. It can be a little worse if the load is too light. To achieve and maintain some kind of balance, place heavier cargo at the front of the axle. Tie down the load if you can too.

Driving too fast reduces mileage on gas, increases wind resistance and causes some strain on the whole system. You are much safer maintaining slower speeds. If your contraption continues swaying yet you have reduced your speed, you might have to reload everything. You could also add a sway control or a weight distribution system that has sway control.

Be sure to do these checks well in advance, especially if you will be doing a weekend trip. Most parts shops close for the weekend until Monday morning and if you find that you need a replacement, you will have to alter the dates for your trip or cancel it altogether.

Maintenance is the thing to do

Looking at the bigger picture, regular maintenance is crucial for any mechanical equipment. It reduces the chance of accidents, improves performance and saves a lot of money and time. It also ensures that you get the most out of the money you spent buying parts and every other accessory required.

Regularly taking a look at your mobile home axles will keep your equipment running for much longer. Collect as much information as you can on proper maintenance and determine when to make changes. This will have you prepared for those times you need to carry out some maintenance tasks without compromising on the quality and accuracy of the final result.

You can be an expert too and seeing your equipment running smoothly after carefully working on it evokes such pride and confidence. Be sure to stay in touch with like-minded individuals who can give you tips and pointers to keep your equipment in good shape. And most importantly, remember to check if your axles need replacement.

What did we miss? What experience do you have with mobile home axles? Feel free to share!